Uses of the air-supported structure

Product Plasteco Milano » About us »

Uses of the air-supported structure

As with many new developments in industry and technology, air-supported structures have also developed from military applications.

The so-called air-supported structures were, and still are, used to create protected areas for warehousing, weapons assembly, vehicle and aircraft maintenance, radar equipment storage, or as mobile hospitals.

Whenever equipment has successfully passed military testing, it soon finds a commercial use and the application of pneumatic construction for buildings was no exception. Military structures were followed by commercial applications, often with excellent results.

Uses of the air-supported structure

This application demonstrates the adaptability of air-supported storage deposits, not only for traditional purposes, but also for the most demanding requirements where strict control of the environment is essential.

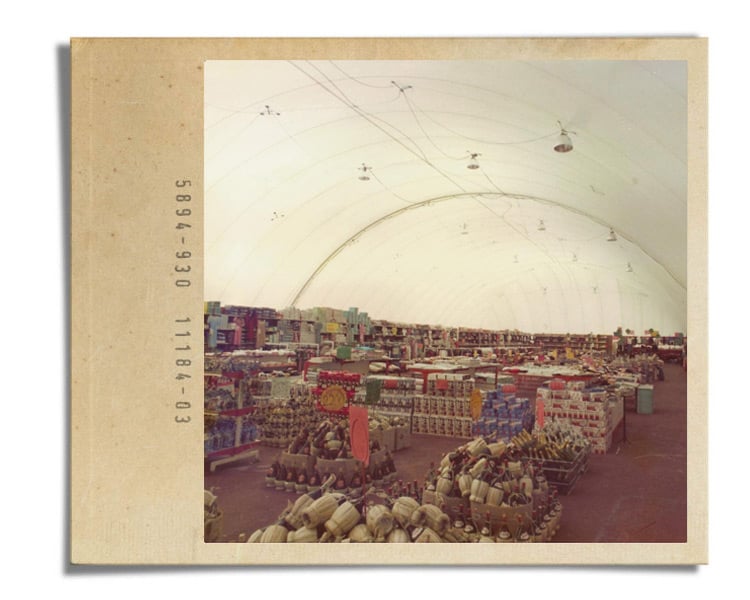

Storage depots

Covered warehouses have always presented a problem for industrial companies because space requirements can vary considerably from one moment to the next and the continuous fluctuations in demand make the construction of permanent buildings impractical.

The air-supported structure or air-inflated structure is a simple membrane supported by air supplied from continuous ventilation systems.

While it is true that the warehouse space can be leased, in addition to the cost, the forced decision of choosing a warehouse located far from the company’s own premises may be one reason for inefficiencies in the reordering of stock.

The air-supported structure is a way to solve this problem, as it provides a space which is enclosed and variable in size.

Although environmental control is not required for many storage applications, some goods such as foodstuffs need to be stored in a tightly controlled environment and this can also be achieved with air-supported structures. Back in the 1980s, a grower in France managed to keep fruit fresh for nine months in a refrigerated warehouse. In practical terms this was three months longer than the period possible with a traditional building and for less than half the capital cost.

Industry

As with variations in the space required for storage, there are also times when production needs to be quickly expanded. In manufacturing industries, production flexibility can be one of the principal factors which ensures commercial success.

Once again, traditional buildings do not allow for rapid changes to available space, while the use of pneumatic structures (depending on the situation and requirements in the self-supporting pneumatic tent version as well) can result in an instant increase in production.

The recovery of a major Italian industrial company in Friuli, following the collapse of the entire facility due to the earthquake in 1976.

The perfect example can be seen in the need to restart a major Italian industrial company located in Friuli, which suffered the total collapse of the entire facility following the 1976 earthquake. In this case, thanks to the commitment of the employees of the company hit by the earthquake and by virtue of an Italian company which supplied an air-supported structure, the entire work cycle was able to resume after only 45 days!

Strict environmental control is essential for many manufacturing processes; companies which manufacture miniaturised electronics require dust-free environments, while the preparation of foodstuffs requires a high level of hygiene.

These are just two of the many production processes that need environments which can be controlled within precise and defined limits, requirements which air-supported structures can easily satisfy.

Construction

In the construction sector, in general, the application of air-supported structures can be highly significant. In winter, the construction phase of a building, especially in countries where the climate is particularly harsh, involves additional costs due to unused labour on days when the weather is bad, the need to protect materials and maintain them at temperatures that allow them to be used.

Allow work to continue in all weather conditions

Inside anair-supported structure, workers are always able to continue their tasks in a comfortable environment.

As a result of being able to cover large spaces, air-supported structures are an appropriate solution for these applications and have been used to great economic advantage in both the military sector, for the assembly of radar equipment, and in the realisation of major civil engineering projects, or even the everyday construction of buildings.

Horticulture/Agriculture industries

Over the years, the growing population has led to the expectation of a similar increase in agricultural production: unfortunately, this hoped-for increase has only occurred in part. Hence the need to be able to make fertile even those parcels of land which, by their very nature, are unsuitable for agriculture and may only be possible through the creation of an artificial environment.

A solution has been found, by moving agriculture inside special installations: these involve large expanses of sand and gravel covered by air-supported structures in which a computerised control system provides an ideal environment for plant life.

These “factories” are characterised by levels of production never before achieved.

Social applications

The air-supported structure has not been as successful in commercial applications as it has been in sports and leisure facilities: sports facilities represent more than 70% of all air-supported structures which have been constructed.

Among sports applications, a special mention must be made ofcovers for tennis courts, which still has the highest percentage of use in the sector.

Air-supported structures in sport

The structures designed to cover swimming pools also achieve interesting heights. The same can be said for covers designed for riding stables, bowling greens, volleyball courts, basketball courts, five-a-side football pitches, ice-skating rinks, school gyms, etc. (see all our applications of air-supported structures for the sports sector)

Ultimately, it could be said that the best test bench for pneumatic structures in Western Europe has been that of sports structures.

The same can be said for covers designed for riding stables, bowling greens, volleyball courts, basketball courts, five-a-side football pitches, ice-skating rinks, school gyms, etc. (see all our applications of air-supported structures for the sports sector)

Another application is their use as exhibition spaces and waterparks. And we must not forget itinerant evangelical churches, extremely popular in the U.S. Then there are the membranes used for biogas and to cover open landfills with immission control and recirculation of odours following the treatment of waste.

In short, where there is a need for a quick cover solution, at low cost, with open spaces of several tens of meters without obstacles, where there is a seasonal or temporary need, and where equally rapid removal is also required, the air-supported cover certainly represents an appropriate solution.

Limits of use

Despite its many positive features, the air-supported structure also has its limitations: the need to maintain a difference in pressure with a continuous supply of air, the need to minimise air leaks, the need to act against lifting forces using anchors and, lastly, the importance of choosing the plastic material.

Ultimately, this structure is more comparable to a facility that needs simple controls and scheduled inspections than a traditional building, and, without a doubt, this significant difference represents a limitation for some and an advantage for others.

Another typical limitation of these types of structure, constructed using thin membranes, is the environmental aspect, more specifically their thermal insulation.

Leave a message Ask for information or a free quote.

Our experts are always at your disposal

Call us

T: +39 02 9986793

T: +39 02 9989701

Opening time 09:00 – 12:30, 13:30 – 18:00

Saturday – Sunday closed

via V.Monti, 3

20030 SENAGO (MI) Italy