The history of the air-supported structure

Product Plasteco Milano » About us »

Pressostatic: History and evolution

The air-supported structure or air-inflated structure is a simple membrane supported by air supplied from continuous ventilation systems. The membrane is securely anchored to the ground.

The main difference between this type of construction and traditional building methods is in their behaviour compared to a classic load-bearing structure. The air-supported structure tends to rise from the ground due to the difference in internal pressure and external pressure; therefore, the actual function of the foundation of an air-supported structure is to provide anchorage.

The slight difference between the internal and external air pressure of the structure is just a few Pa; 150 Pa is sufficient to support any structure. Of course this value must be revised in accordance with the changes in the weather.

The air-supported structure or air-inflated structure is a simple membrane supported by air supplied from continuous ventilation systems.

The air-supported storage structurewas developed in the post-war period to meet the needs of the U.S. Military and later evolved into a wide variety of uses.

We can easily presume that today, air domes now cover several million square metres of surface area, and for the widest possible variety of use; as well as sports facilities (swimming pools, tennis courts and five-a-side football pitches), they are also used for waterparks or large-scale events, industry, agriculture, landfills, etc. In all their years of use, no objections have ever been raised with regard to the safety of the product, which has shown great versatility of use, alongside their low cost and minimal construction times.

The air-supported structure arrived in Italy about 70 years ago as cover for tennis courts and has proved, right from the beginning, to be a very simple, economical product which is ideal for the purpose for which it was designed. Obviously, in recent years, the product has undergone an evolution specifically aimed at improving comfort and energy savings; in fact, it evolved from a simple membrane to a double membrane over twenty years ago, while the heating systems used have been continuously improved to achieve significant reductions in energy consumption while maintaining, if not improving, the comfort level of the interior environment.

Air-supported structure: History

While many new technical developments have emerged from military applications, this is also true forpneumatic structures.

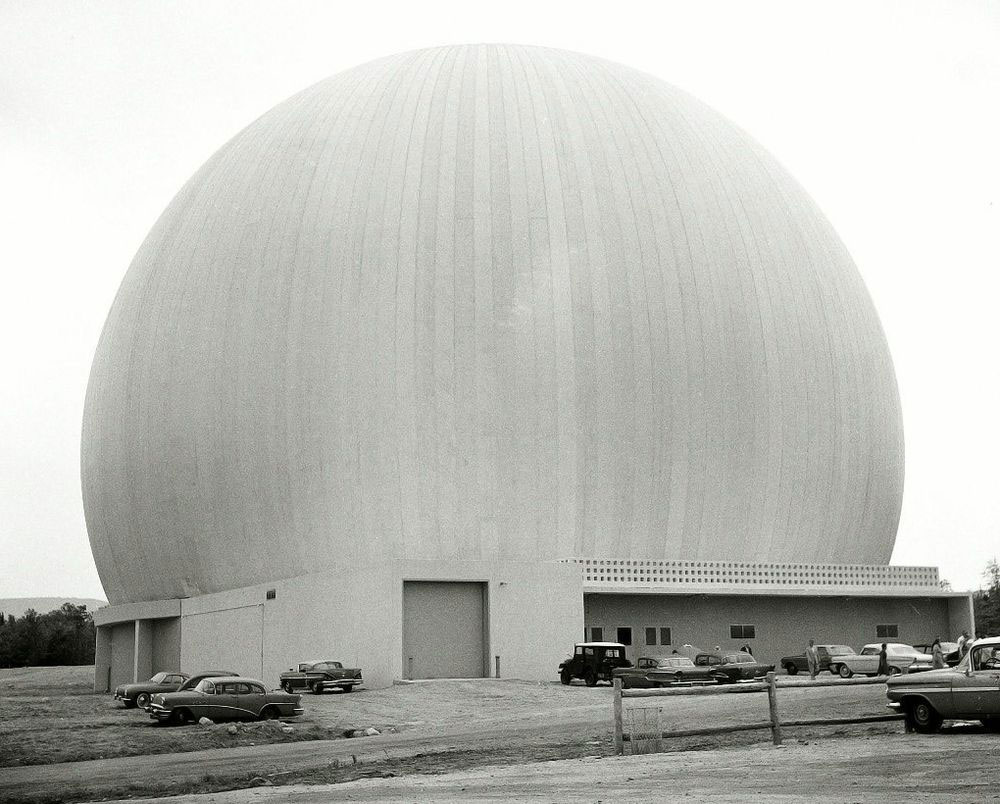

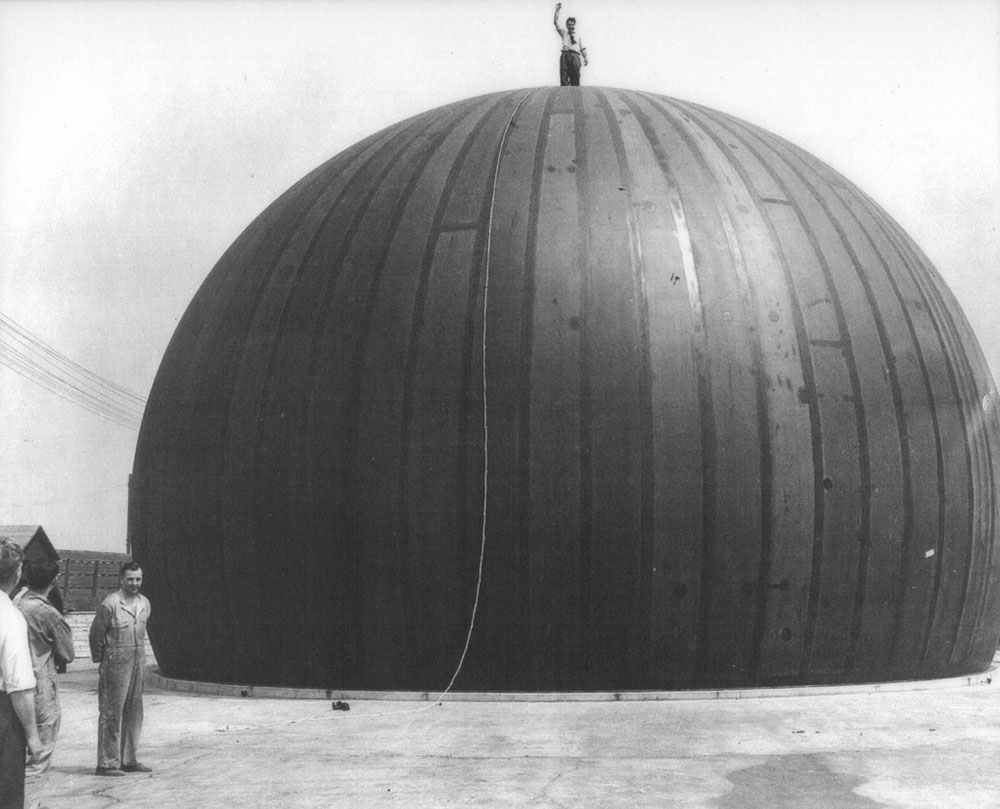

The first air-supported structures were the DEW line domes in Alaska, used to shelter radar equipment from the inclement weather. The excellent performance of these domes, subjected to severe climatic conditions, proved the practicality of this type of structure,once and for all.

While many new technical developments have emerged from military applications, this is also true for pneumatic structures.

While many new technical developments have emerged from military applications, this is also true for pneumatic structures.

Since the early post-war period, this type of construction has found wide range of military applications; in fact, air-supported buildings were used, and still are, as warehouses, the assembly military weaponry, vehicle and aircraft maintenance, protection for radar equipment, mobile hospitals, etc.

The first known attempt to apply the principles of the air balloon to structures that do not rise into the sky was by the English engineer Frederick William Lanchester (Lewisham, 23 October 1868 – Birmingham, 8 March 1946).

In his 1917 patent for a field hospital, the basic principles of pneumatic construction were applied:

“the present invention aims to provide a means of building and erecting a large tent without the use of poles or supports of any kind. The invention consists of the construction of a tent in which the fabric of the balloon or other low-permeability materials are supported by air pressure, whose inlet is provided by one or more airtight chambers…”.

This patent, derived from the construction of balloons and airships, is of great importance for two reasons: firstly, because it seems to already demonstrate an awareness of all the basic applications of air-supported buildings and, secondly, for the ability to cover large spaces such as hangars and playgrounds.

Later, in 1938, Lanchester looked into the possibility of much larger pneumatic constructions. He prepared sketches for a building to be used for exhibitions with a diameter of 330 m; the first structure was not assembled, however, until 30 years later due to the Second World War and the industrial crisis that stopped all experimentation.

A patent derived from the construction of balloons and airships

A patent derived from the construction of balloons and airships

Lanchester’s ideas were so far removed from the static and cumbersome concepts of traditional construction that other designers of the time did not accept them; moreover, doubts about their application were further increased by the disastrous accidents involving airships.

Despite the fact that Lanchester failed to realise his designs, he can still be called the “father” of pneumatic construction.

The first buildings supported by the air

The Second World War was responsible for intensive research into pneumatic structures for very special applications such as captive balloons and fake buildings and vehicles for purposes of deception, but it was only in 1946 that Lanchester’s ideas came to fruition.

The United States had constructed large radar antennas to protect the northern border from invasions and which had to be sheltered from the harsh weather conditions with a cover that subjected radar waves to minimum interference. The use of a membrane supported by air pressure alone was therefore required and the US government awarded the contract to the workshop to determine the feasibility of pneumatic structures for this application.

A portable low-cost structure that could be assembled and disassembled in one day.

A portable low-cost structure that could be assembled and disassembled in one day.

In the years following the erection and testing of the first prototype, hundreds of these air-supported domes were constructed for Alaska. At the same time, materials such as nylon or terylene fabric, coated with a synthetic layer of neoprene, vinyl or hypalon and capable of withstanding the harshest conditions consisting of fabrics, were developed.

The first commercial applications of pressure switches

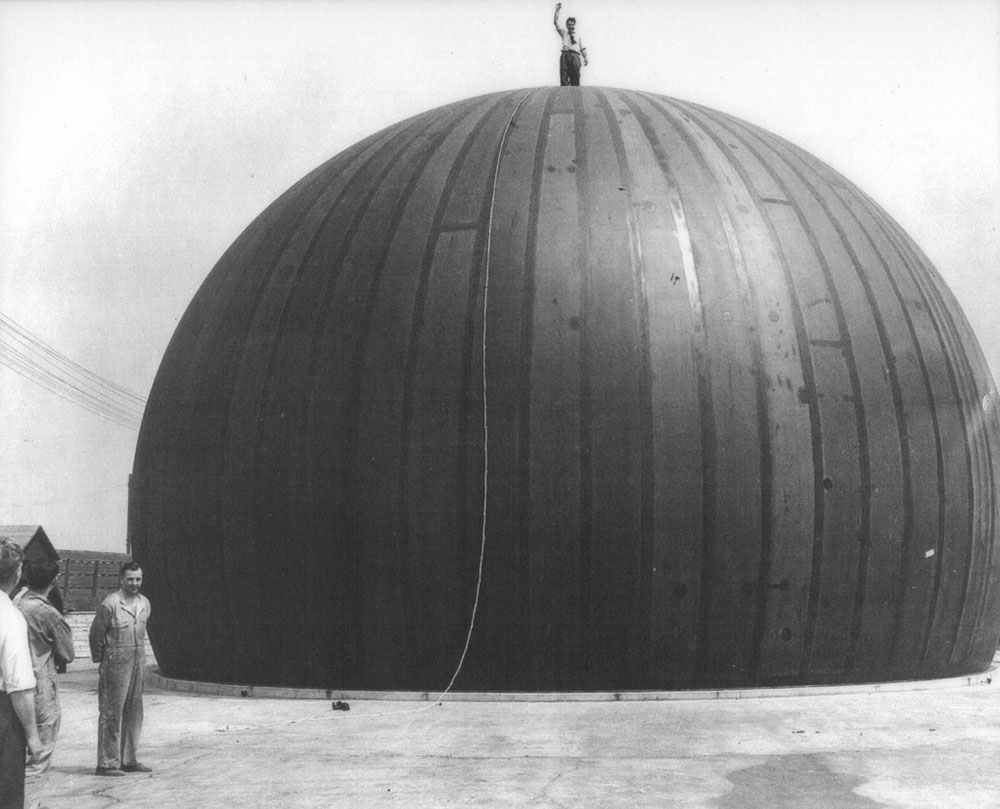

Following the success of these domes, a company was created to design and construct pneumatic structures, and in January 1956 Birdair Structures Incorporated opened for business.

Despite the knowledge of pneumatic structures acquired by Birdair, the first company to build an air-supported warehouse for commercial use was CID Air Structures. From here began the great pneumatic structure business in the U.S.

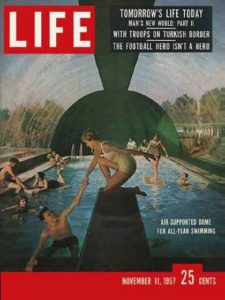

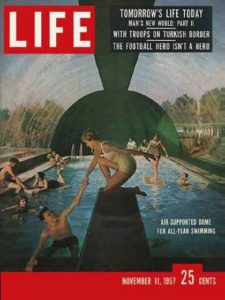

Manufacturers of tents and parachutes began to build simple air-supported buildings and, around 1957, about 50 American manufacturers used the characteristics of air-supported structures to cover sports and military facilities, exhibition centres, warehouses and factories.

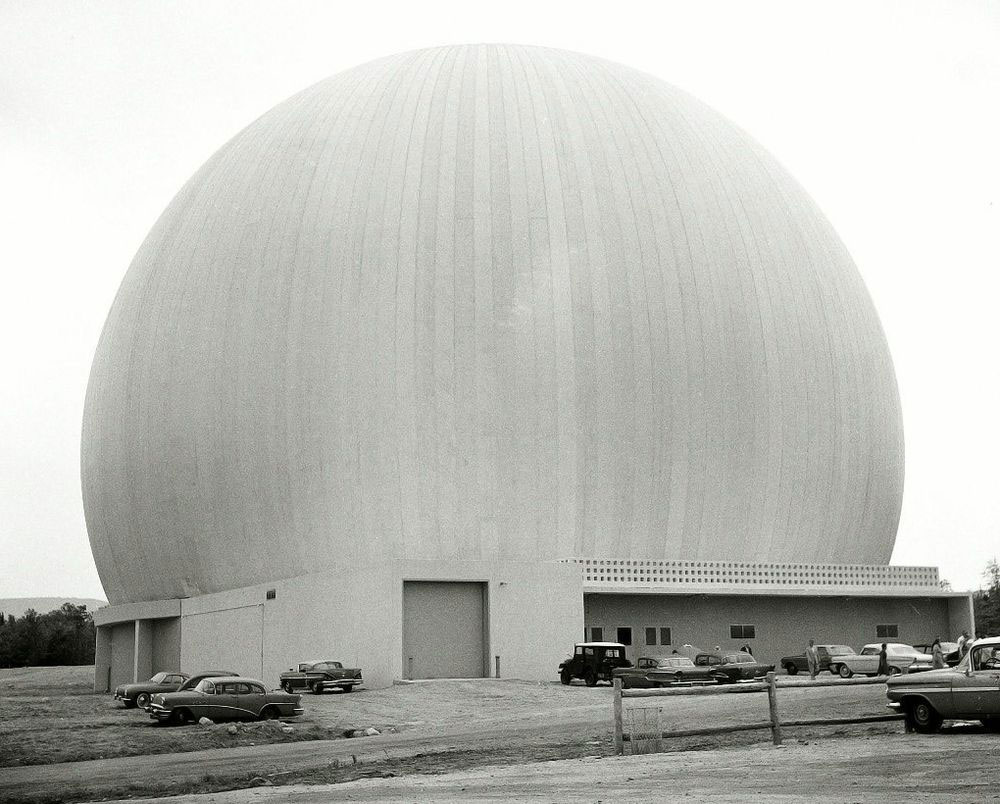

The advantage of these structures was that large areas could be covered at low cost and using a portable structure that could be assembled and disassembled in a day. The pneumatic structure was a novelty that attracted a great deal of publicity, and it wasn’t long before the United States built hundreds of these “bubbles”.

Continuously resupplying the structure with air to maintain stability is required to prevent excessive air leakage through the inlets; this consideration led to the creation of an inflated structure with double wall. Following the Second World War, this type of construction was studied in both America and Great Britain and it was used by both countries for military purposes or polar shelters.

Air-supported buildings were considerably cheaper and had greater structural stability.

Investigations of inflated buildings demonstrated that air-supported buildings were considerably cheaper and had greater structural stability. As a result of this, “hybrid” structures were developed where auxiliary structural elements were used, in combination with air-supported construction, to protect the structure from a sudden collapse in the event of a failure of the air supply and to simplify the inlets.

Economic assessments therefore led manufacturers to focus more on simple air-supported structures as they promised better commercial viability. Around 1960, Europe and Japan also began to take an interest in these new buildings.

At first Great Britain, then Sweden and Germany managed, in just a few short years, to achieve a level of quality and quantity comparable to that of the United States; later, in 1970, every European country and some in the Eastern bloc became manufacturers of pneumatic structures.

The beginnings in Italy

It was not only America that worked on the ideas of engineer Frederick William Lanchester: Italy had its own inventor of air-supported structures (even if he could be defined internationally as a pseudo-inventor), G. Rocca who, in the first few years following the Second World War, formed a small marine salvage company.

Marine salvage was carried out by means of “airbags”, i.e. huge flexible rubber containers (caissons) which were placed inside the holds of the ships. Once inflated, they were able to raise the ship to the surface.

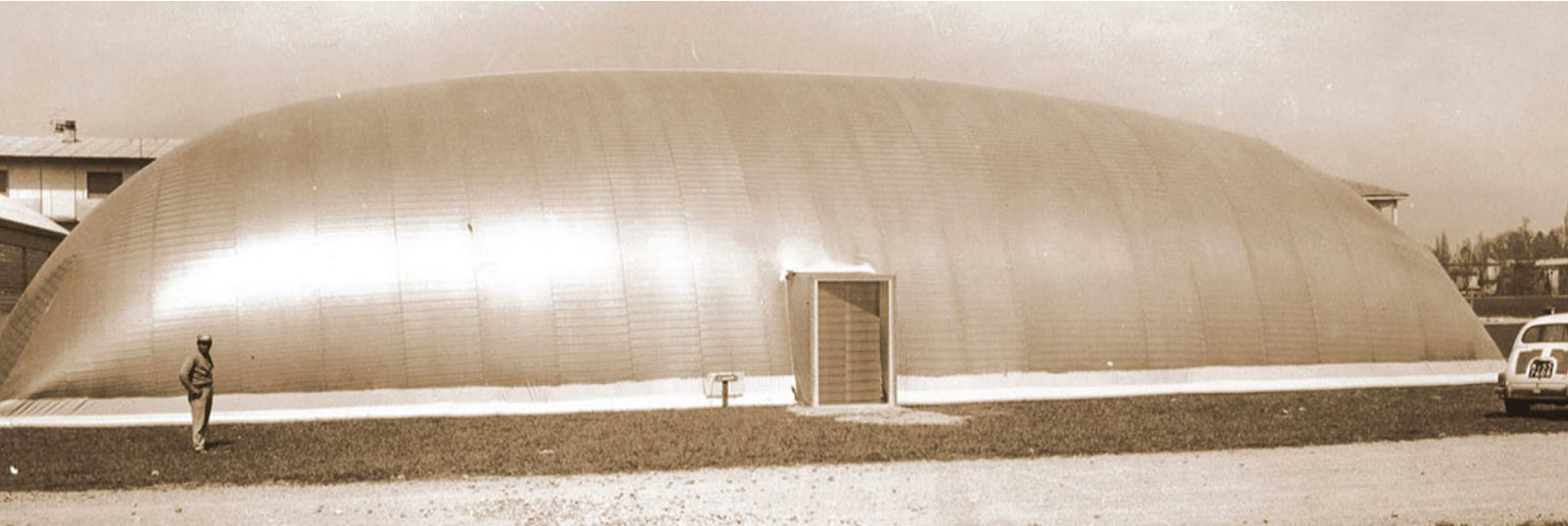

In 1952, tests were being carried out on one of these airbags to check for air leaks. Due to an oversight, the base of the container was not applied before it was inflated and it was found that, despite the significant amount of air leakage, it remained inflated. It was later anchored to the ground using bags of sand and it was found that, inside the “bubble”, an obstruction-free environment was created which was ideal for carrying out an activity.

The following year, Mr. Rocca built the first structure for personal use; in fact, he had to temporarily expand his company. In doing so, he erected the world’s first air-supported structure for commercial use.

After this happy beginning, Rocca resumed his marine salvage business until 1957 when, following a shipwreck with the loss of his boat, he abandoned this sector to devote himself fully to the construction of air-supported structures. In 1959, he founded C.P.V. in Mestre which, during its short existence, managed to build over 100 structures.

On the back of this initial push, and in the light of American successes, other companies timidly entered the air-supported structure market in Italy.

Published by Tsport

Written by Claudio Cigognetti

Leave a message Ask for information or a free quote.

Our experts are always at your disposal

Call us

T: +39 02 9986793

T: +39 02 9989701

Opening time 09:00 – 12:30, 13:30 – 18:00

Saturday – Sunday closed

via V.Monti, 3

20030 SENAGO (MI) Italy